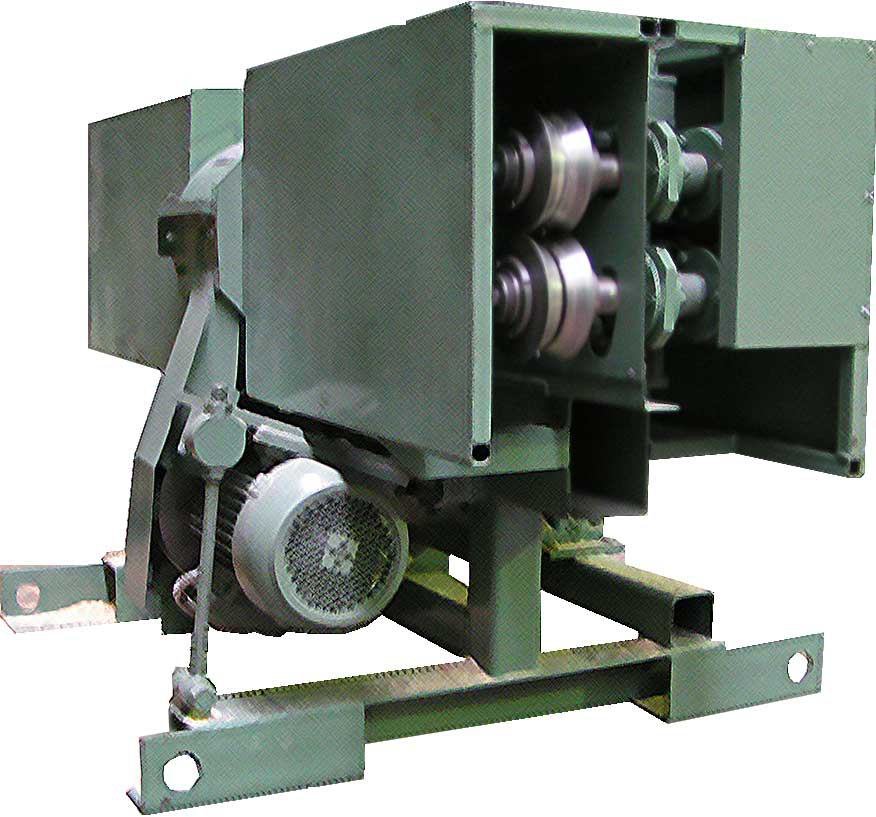

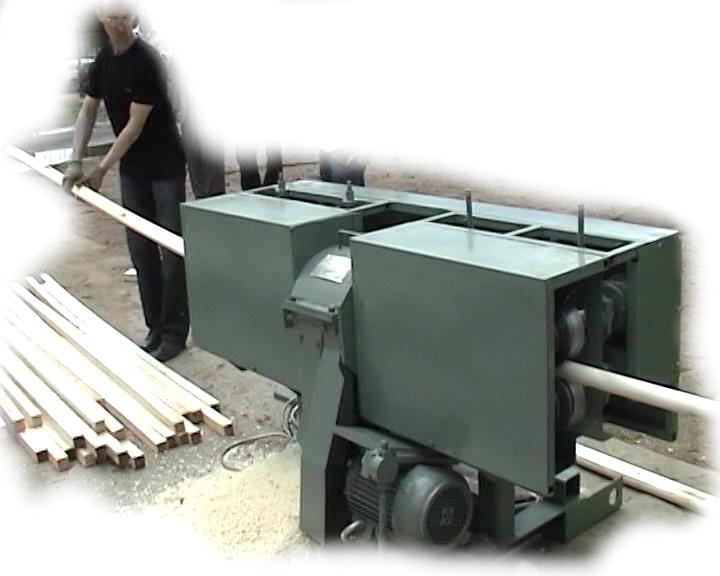

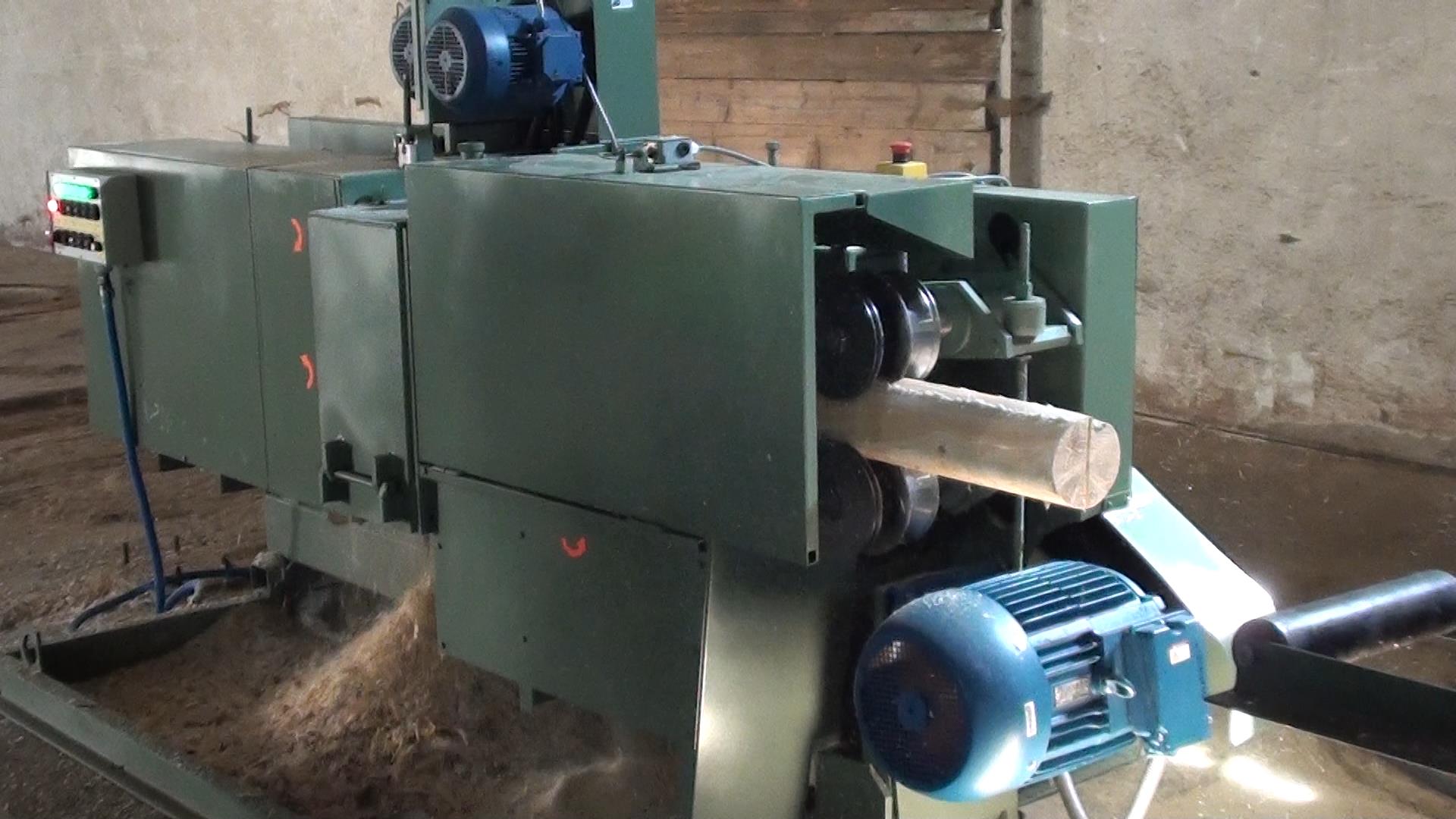

Woodlandia Log Rounders

Woodlandia Machines of LR series

Woodlandia offers line of machines for log rounding purposes. The line includes machines for the processing of small diameter logs from 2¾” (70mm) up to 17¼” (440mm) in butt diameter.

For processing of small logs Woodlandia recommends LR-160S (former RLM-160S), LR-160 (former RLM-160), LR-100 (former RLM-100). For larger logs the LR-200 and LR-320 are more suitable.

These log through-pass machines with the rotary type milling head produce round dowels from raw barked logs in one pass. RLM-160S machine can also perform rip-sawing operation on dowels.

Throughput of the machine varies depending on the model. Please refer to the specification below for actual numbers.

Pictures

|

|

|

|

||

|

||

SPECIFICATION of Log Rounding Machines of LR series

|

|

LR-40 |

LR-60 |

LR-80 |

LR-160 |

LR-160S |

LR-240| |

LR-320 |

|

Output dowel range: |

¾” – 1½” 18 -x 40 mm |

¾” – 2⅜” 18 - 60 mm |

1¾” – 3⅛” 38 - 80 mm |

2½” - 6¼” 60 - 160 mm |

2½” - 6¼” 60 - 160 mm |

4¾”(3⅜”) - 8” |

6¼ – 12½” 160 - 320 mm |

|

Input raw log (stem) range: |

Only works with small planks: 2x2” (50x50mm ) |

2¾” – 4” 70 x100 mm or planks up to: |

3¼” – 4¾” 85 x 120 mm or planks up to: |

Min tip - Max butt:

3¼” – 9½” 85 – 240 mm |

Min tip - Max butt:

3¼” – 9½” 85 – 240 mm |

Min tip - Max butt: 5½” – 12½” 4" – 12½” |

Min tip - Max butt:

7” - 17¼” 180 – 440 mm |

|

Min length of the input log: |

28” (0.7 m) |

40” (1 m) |

40” (1 m) |

63” (1.6 m) |

63” (1.6 m) |

6½ ft (2m) |

6½ ft (2m)

|

|

Feeding speed: |

19½; 29½; 39 ft/min ( 6; 9; 12 m/min ) |

10-26 ft/min 3-8 m/min |

8-26 ft/min 2.5-8 m/min |

3-26 ft/min 1-8 m/min |

|||

|

Power of the milling motor(s) |

4 HP (3 KW) |

7.4 HP (5.5 KW) |

14.75 HP (11 KW) |

Rounding: 30 HP Milling: |

Rounding: 30 HP (22 KW) Profiling + Ripping: 2*15 HP+15 HP 2*7.5 KW+11 KW |

50HP 37 KW

|

74 HP 55KW

|

|

Power of feeding motor(s) |

0.74 HP (0.55 KW) |

1.47 HP (1.1 KW) |

2 x 2 HP |

2 x 2 HP |

2*2 HP 2*2 KW |

2*2 HP 2*2 KW |

|

|

Cross cut (milling) saw capability |

N/A |

N/A |

N/A |

N/A |

Yes |

||

|

Milling cutter head frequency |

5000 rpm |

4000 rpm |

3000 rpm |

Rounding: 1600rpm |

Rounding: 1600 rpm Ripping: 2200 rpm |

1000 rpm |

900 rpm |

|

Dimensions |

44 x 48 x 44” 1.1 x 1.2 x 1.1 m |

67 x 48 x 44” 1.7 x 1.2 x 1.1 m |

71 x 79 x 52” 1.8 x 1.3 x 1.4 m |

130 x 79 x 81” |

130 x 79 x 81” |

16 x 6½ x 6¼ ft |

34 x 8 x 5 ft |

|

Weight |

992 lb (450kg) |

1653 lb (750kg) |

1874 lb (850kg) |

5512 lb (2500kg) |

5732 lb (2600kg) |

8150 lb (3700kg) |

12125 lb (5500 kg) |

It is important to know in beforehand the following facts about this machine:

- By default the machines are made for European 3-phase 380V/50Hz power

- Smaller machines can be supplied with optional phase converter to turn single phase into 3 phase

- All parts are metric

- Proper automated waste removal system is critical as bad waste management can drastically affect productivity

- Log sorting is necessary for better productivity

- For max productivity automatical in-feed and out-feed log decks as well as in-feed and out-feed conveyors are recommended

- Speed of automated in-feed conveyor is to be adjustable to synchronize with in-feed speed of LR-machine.

- LR machine' rotary head can remove up to 5cm (2") on radius or 10 cm (4") on diameter of the log. It means that butt diameter of input raw log must be not more than 4 inches than its top diameter. For example if output product (dowel) diameter is to be = 3½" and top dia of raw log is 4" than max diameter of log butt is to do not exceed 3½" + 4" = 7½"

Terms

-

Payment terms (USD, CAD, EURO): 50% upfront, remaining to be paid before delivery by instalments

-

Delivery requires either one 40 ft or 20ft sea container (depending on a machine model). For delivery quotation contact us (postal or ZIP code of a destination is required)

-

All LTPS-machines are built by special orders only (usually no inventory, but some popular models can be in stock)

-

Please allow 60-150 days for manufacturing and delivery

-

Limited warranty (parts only) covering bearings, electrical components, motors is provided..USA & Canada: 1 year, world-wide; 6 months.

-

By special order NEMA-compatible motors can be installed on LTPS-machines (by default all LTPS-machines electrical parts are for European 3phase 380V, 50Hz power)

-

CSA/ULC/CE certification is optional

-

Please inquire for our price lists and extra technical info