RoundMaster solutions

What is RoundMaster? What is purpose of RoundMaster?

- The RoundMaster is a complex of machines for the manufacturing of house logs of round profile with lengthwise Swedish cope.

- In conjunction with log lathe LL-41, the RoundMaster is the solution for the optimizing of the production process, increasing of productivity and adding of more variations to milled log home designs.

- The RoundMaster is an efficient solution for small and medium size business where full automation is not required.

- The RoundMaster production line should work simultaneously with the log lathe or log profiling machine.

Benefits of RoundMaster

- On average, in comparison with a similar configuration without

RoundMaster, use of the RoundMaster allows to gain:

- about 25% of production time

- about 35% in productivity

- 1-4% of cost (this number was calculated basing on average wage rate = $30/h, in areas where rate is less than $30/h cost effectiveness of the RoundMaster will be proportionally much more than 4%)

- The RoundMaster can help to increase productivity of a log home manufacturing enterprise by paralleling of log processing operations.

- Productivity increase is achieved because dedicated notch making machine works in parallel with one, two or three log lathes.

- The RoundMaster can work alongside with log profiling machine or other log lathe.

- The RoundMaster allows increased variations of log home designs because the dedicated notcher NM-1 is able to mill notches in different angles.

- The RoundMaster can be a good choice for those who need economical log home manufacturing solution

What does RoundMaster consist of? What are its functions?

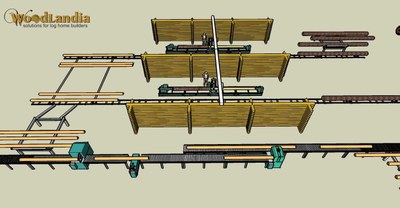

RoundMaster consists of:

- 1 log cross-cut machine LT-1

- 1 log notching machine NM-1

- 1 log mortising machine LJ-1

- set of roll tables (total 16m in length) for easy log transportation and manipulation

Optional: log decks, conveyors

Examples for RoundMaster based solutions

1 RoundMaster manufacturing complex can work simultaneously with up to

3 log lathes LL-41.

- RoundMaster-1 consists of RoundMaster manufacturing complex + 1 log lathe LL-41

- RoundMaster-2 consists of RoundMaster manufacturing complex + 2 log lathes LL-41

- RoundMaster-3 consists of RoundMaster manufacturing complex + 3 log lathes LL-41

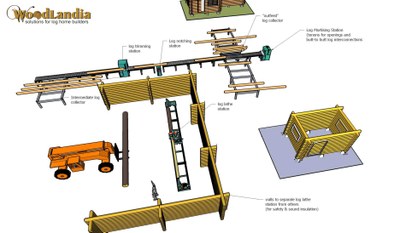

RoundMaster-1: Simple layout

This is an example of most simplest RoundMaster solution. Logs are moved to/from the log lathe by forklift. Such concept can be used when minimum $$$-amount should be invested into infrastructure and/or quickest manufacturing start is required.

|

|

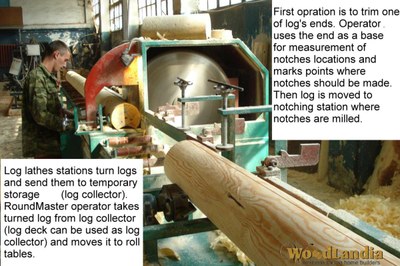

RoundMaster-1: real life example in pictures

|

|

|

|

click on the picture to enlarge

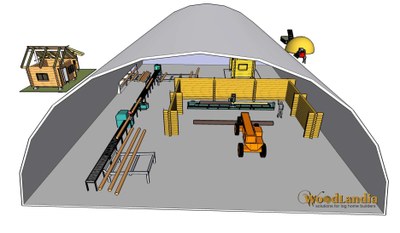

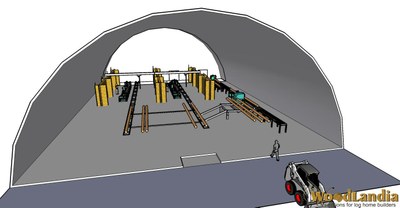

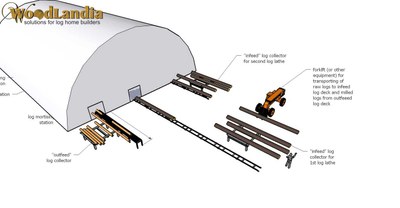

RoundMaster-1: example with log conveyor

- This solution requires a custom made log transporting conveyor system in order to move raw logs from “in-feed” log deck to log lathe station.

- Then using the same transporting system, turned logs can be delivered to intermediate collector.

- Next the log is directed to RoundMaster line.

|

|

click on the picture to enlarge

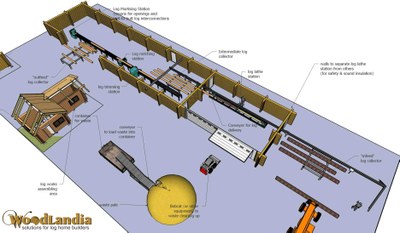

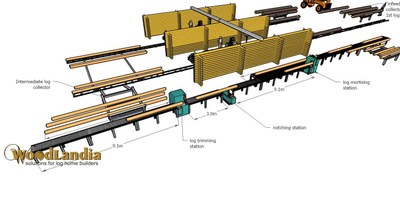

RoundMaster-2: example with rail cart log transporting system

- Sorted by diameter logs are delivered to “in-feed” log decks (each log lathe has a dedicated in-feed log deck). Then one log is moved to a rail-way cart and the cart delivers the log to log lathe station. The log is setup on the lathe using manual or motorized chain hoist device. The cart is directed to in-feed log deck for loading of next log. Loading of the log to the cart can be done simultaneously with log turning process by helper.

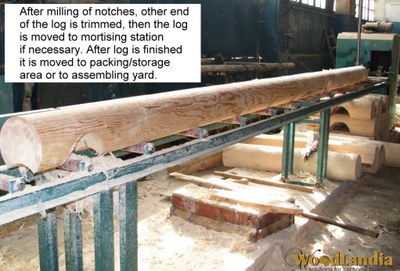

- After processing of the log, it is moved to other rail-way cart which delivers the log to intermediate log collector. The operator of the RoundMaster line takes logs from the collector and moves them on roll-tables to log trimming station, and if necessary to notching and log mortising stations. The finished log is labeled and moved to “out-feed” log deck.

- Optionally logs can go through spraying system for chemical treatment. From there logs are directed to log assembling yard or to warehouse.

|

|

|

|

click on the picture to enlarge

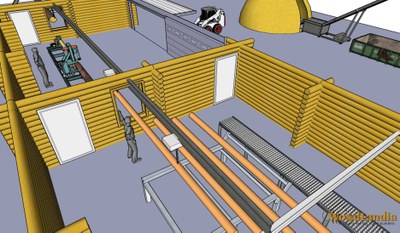

RoundMaster-3: real life example in pictures

|

|

|

|

click on the picture to enlarge

Please contact us if you are interesting in these solutions