Log machines of RLM series

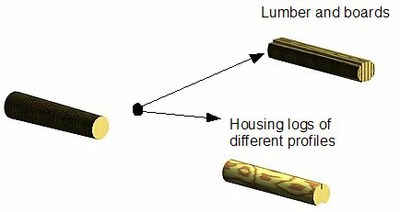

RLM log machine (also known as log moulder, log profiler, log planer, log rounder, log rounding machine) are mighty, robust, effective and efficient solution for a business milling lumber, squared timbers, round dowels or house logs

A purpose of RLM® Log Mill

RLM = Rotary Log Mill (or Rotary Log Moulder).

RLM is a sawmilling plant in one machine. Log mills of RLM series are used in the saw/lumber milling and log home building industries

|

|

Please note: this is just an example of profiles |

What RLM® machine can mill?

Rotary Log Mill (RLM) can mill following profiles effectively and efficiently just in 1 pass:

Why RLM® machine?

There is no similar equipment in same price range with productivity close to productivity/quality of Woodlandia RLM log mills.

RLM log mills are much more flxible and efficient than:

- most of band sawmils on the market

- most of duble-cut sawmills on the market

- any log lathe intended for profiling of house logs

- competitive machines of other manufacturers utilizing same principles

Beside that

- RLM machines are high performance machines using "one pass → all done" idea

- RLM machine can mill up to 5000 linear feet of raw logs per 8-hour workshift (depending on a model, wood species, profile, infrastructure, etc)

Some of our clients report they mill up to 5000 board foot per hour

Some of our clients report they mill up to 5000 board foot per hour- RLM machines can mill barked or debarked, dry or "green" stems in one pass

- Logs can be processed to required profile in one pass

- Unlimited log length (actually the length is limited only by the max butt diameter depending on the RLM machione model)

- Diversity of output log profiles: dimensional & custome lumber, sqaured timbers, round dowels, post, poles. fensing elements, siding, log home materials

- Inexpensive maintenance (knives can be sharpened on a bench grinder or optional knife grinding machine)

- Heavy duty design

- Robust & reliable (if greased in time)

- Able to work from -16 to +30 C

- RLM-technology has been developed and used since 1990

- RLM is patented "know-how" technology

The principles of RLM® Mills

- RLM stands for Rotary Log Mill or Rotary Log Moulder

- RLM machines use the through-pass log milling principal

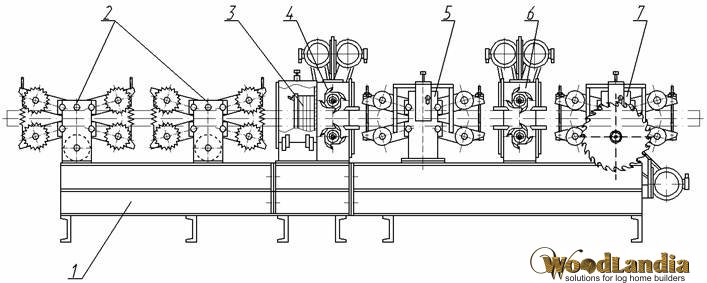

- RLM-machine has 1 Rotary type milling head and 3 to 5 (depending on a model) profiling/sawing spindles

- The rotary milling head has number of knives which spin around the moving log

- Logs are automatically fed into the milling head and then are turned into into required profile or milled into lumber & timbers by cutters and sawblades installed on profiling/sawing spindles

| Rip-sawing into lumber | Rip-sawing | Profiling |

|---|---|---|

|

|

|

- The profile shape is depended on used tooling.

- The profiles are customizable

- The machine is supplied with the tooling for two basic profiles: 1. Round dowel 2. Swedish Cope

- To change tooling (to go from one profile to another) may take 1- to 4 hours depending on complexity of a profile and skills of the technician

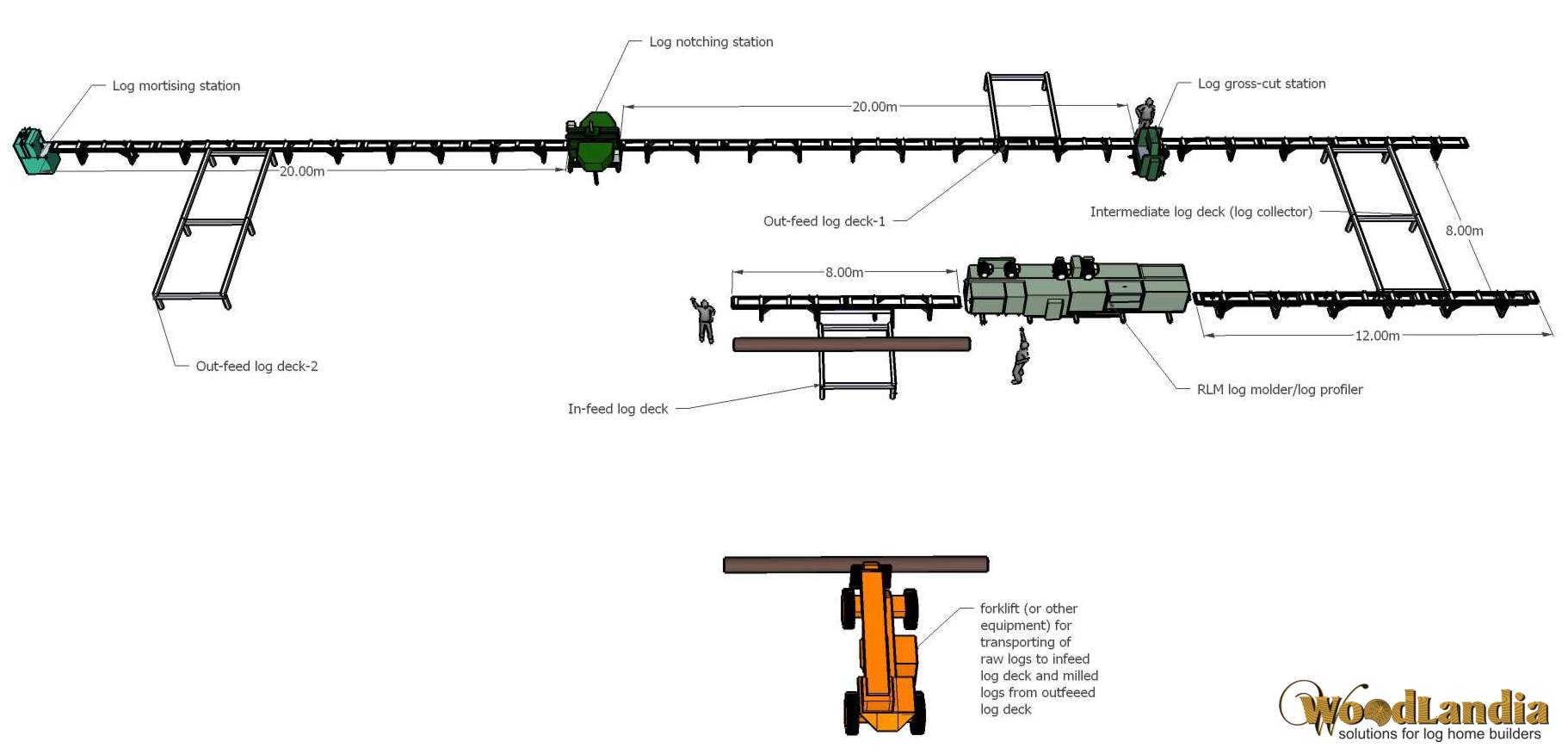

Here is the simple scematics of most popular machine of this type RLM-320MF

| RLM machine schematics (RLM-320MF) |

|---|

|

|

Demo videos

Who may need RLM® machine?

- Small and medium size business milling lumber, sqared timbers, round dowels, fencing elements, house logs

- Small or medium size sawmilling business looking for a way to increase the productivity

- A business who wish to divercify or get into new markets effectively & econimically

- A business who needs one machine able to prodice different types of products

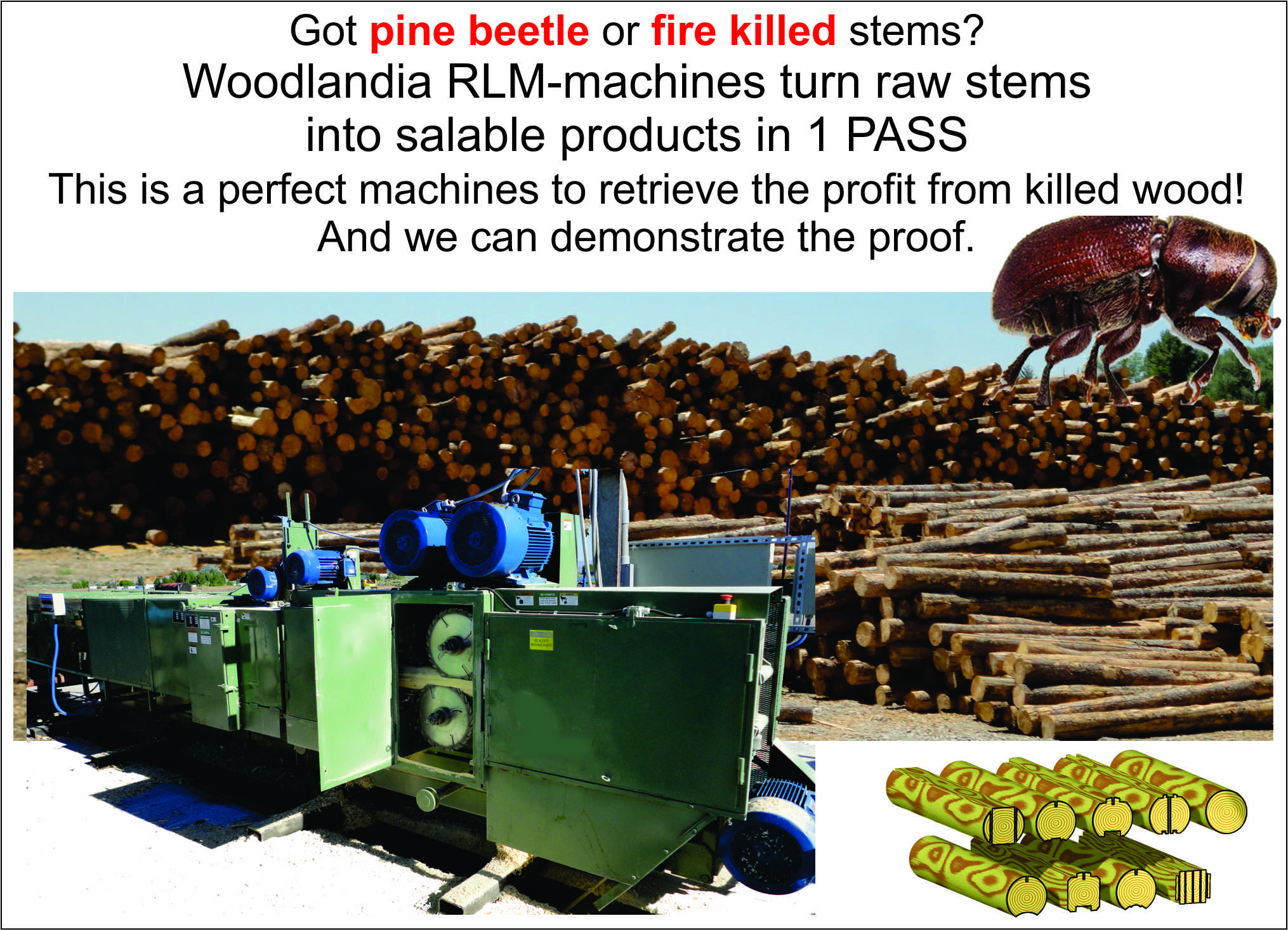

- Those who need to utilyze the pine beetle killed stems by milling them into building materials efectively and econimically

- A small or medium wood-processing business looking for a way to increase the productivity

We offer several models of RLM® log mills

- RLM-160 for small logs with butts up to 240mm (9 1/2")

- RLM-200 for small logs with butts up to 260mm (10 1/4")

- RLM-260 for logs with butts up to 360mm (16")

- RLM-320MF (the most versatile machine in the family) for logs with butts up to 440mm (17 1/4")

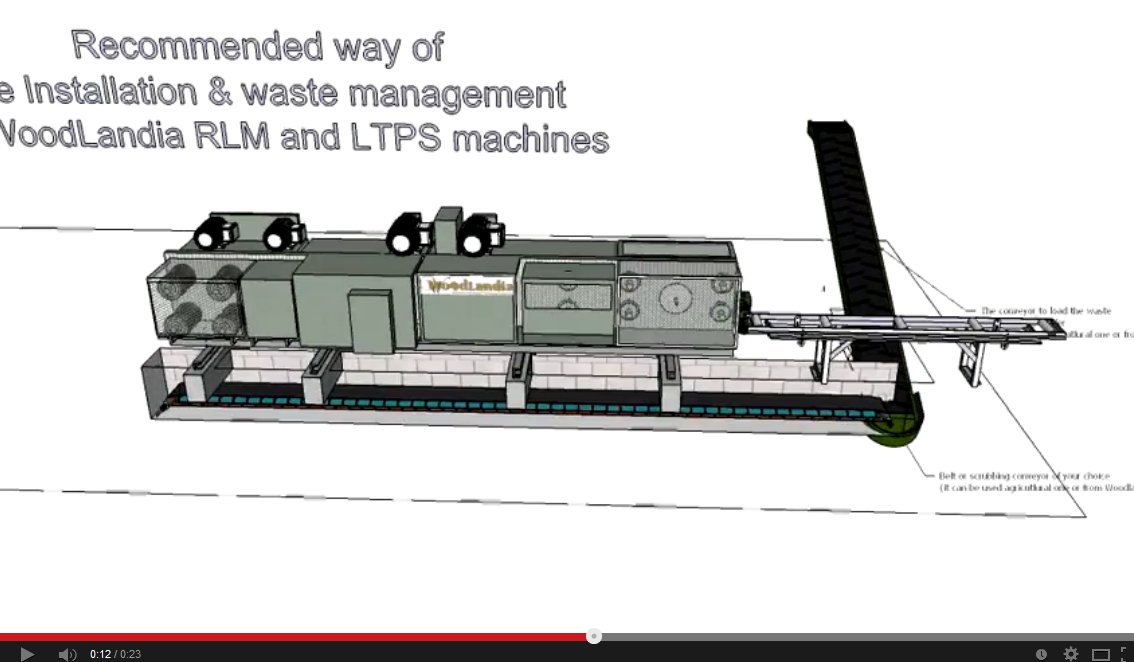

It is important to know in prior following facts about RLM-machines:

- all parts are metric

- proper automated waste removal system is critical because poor waste management can badly affect productivity

- log sorting is necessary for better productivity

- for max productivity automatic in-feed and out-feed log decks as well as in-feed and out-feed conveyors are recommended

- speed of automated in-feed conveyor is to be adjustable to synchronize with in-feed speed of RLM-machine.

- RLM machine' rotary head can remove up to 5cm (2") on radius or 10 cm (4") on diameter of the log. It means that butt diameter of input raw log must be not more than 4 inches than its top diameter. For example if output product (dowel) diameter is to be = 12" and top dia of raw log is 13" than max diameter of log butt is to do not exceed 12" + 4" = 16"

About productivity of RLM log moulders

Woodlandia RLM machines are most effective equipment in terms of cost/productivity.

The productivity greatly depends on:

- Motor power (machine with more powerful motors will be more productive);

- Wood species density and moisture content (hardwood is harder to mill, frozen wood maybe harder to mill);

- Wood reduction (how much wood needs to be turned into the waste);

- Number of saw-blades and cutters installed (more saw-blades = more resistance = more power required);

- Condition of the saw-blades and cutters (dull tooling does not work, right angle for the saw-blades theeth and knife tips is also important);

- Infrastructure & waste management;

- People (yes, people matter as knowledgeable, responsible, caring personnel is one of keys of the success and trouble free operation);

For example:

- Let's assume one needs to mill 6x6";

- 6x8"x16ft = 64 board feet per piece;

- Let's assume the mill works 45 minutes per hour during 8 hours workshift = 360 min/workshift (some time maybe needed for the tooling change, cofee breaks, etc);

- If we assume that the logs are fed almost butt to butt into the mill working with average speed 20ft/min (6m/min) and it can mill 1 such logs per minute then it is 360 16-footers per workshift;

- It means that RLM-320MF theoretically can mill 23,040 board foot of 6x8"x16ft per workshift, what is 54.43 cubic meters;

Please note: - These numbers make sense only for the 6x8"x16ft.

- The actual speed depends on few factors (see above);

- Other profiles can result in significantly smaller production numbers.

For example, for 4x4"x16ft the productivity would be different as 4x4"x16ft = 21.33 boardfoot per piece.

So during the work-shift one theoretically can mill:- from 360 pcs of 4x4"x16ft what is 7,680 board foot or 18.12 cubic meters;

Even better productivity (up to 5000 ln ft) can be achieved if automatic log infeed/outfeed equipment and proper log sorting are used.

| Click here to overview info, pictures and videos of MultiLog production line based on log moulder RLM-320MF |

|

Terms

- Payment terms (USD, CAD, EURO): 50% upfront, remaining to be paid before delivery by instalments

- Delivery requires either one 40 ft or 20ft sea container (depending on a machine model). For delivery quotation contact us (postal or ZIP code of the final destination is requireds)

- All RLM-machines are built by special orders only (usually no inventory, but some popular models can be in stock)

- Please allow 90-240 days for manufacturing and delivery

- Limited warranty (parts only) covering bearings, electrical components, motors is provided. USA & Canada: 1 year, world-wide; 6 months.

- By special order NEMA-compatible motors can be installed on RLM-machines (by default all RLM-machines electrical parts are for European 3phase 380V, 50Hz power)

- CSA/ULC/CE certification is optional

- Please inquire for our price lists and extra technical info

Pictures

Click on a picture to open it in full size in new window

|

|

|

|

|

|

|

|

|

PLEASE NOTE: |