Woodlandia products

| Machine code | Brief description | Notes |

|---|---|---|

|

CLP-1 |

CLP-1 emulates drawknife peeling process of hand crafted log home industry 1. Automated Debarking & Peeling |

NEW PRODUCT! Available in |

|

LL-41 |

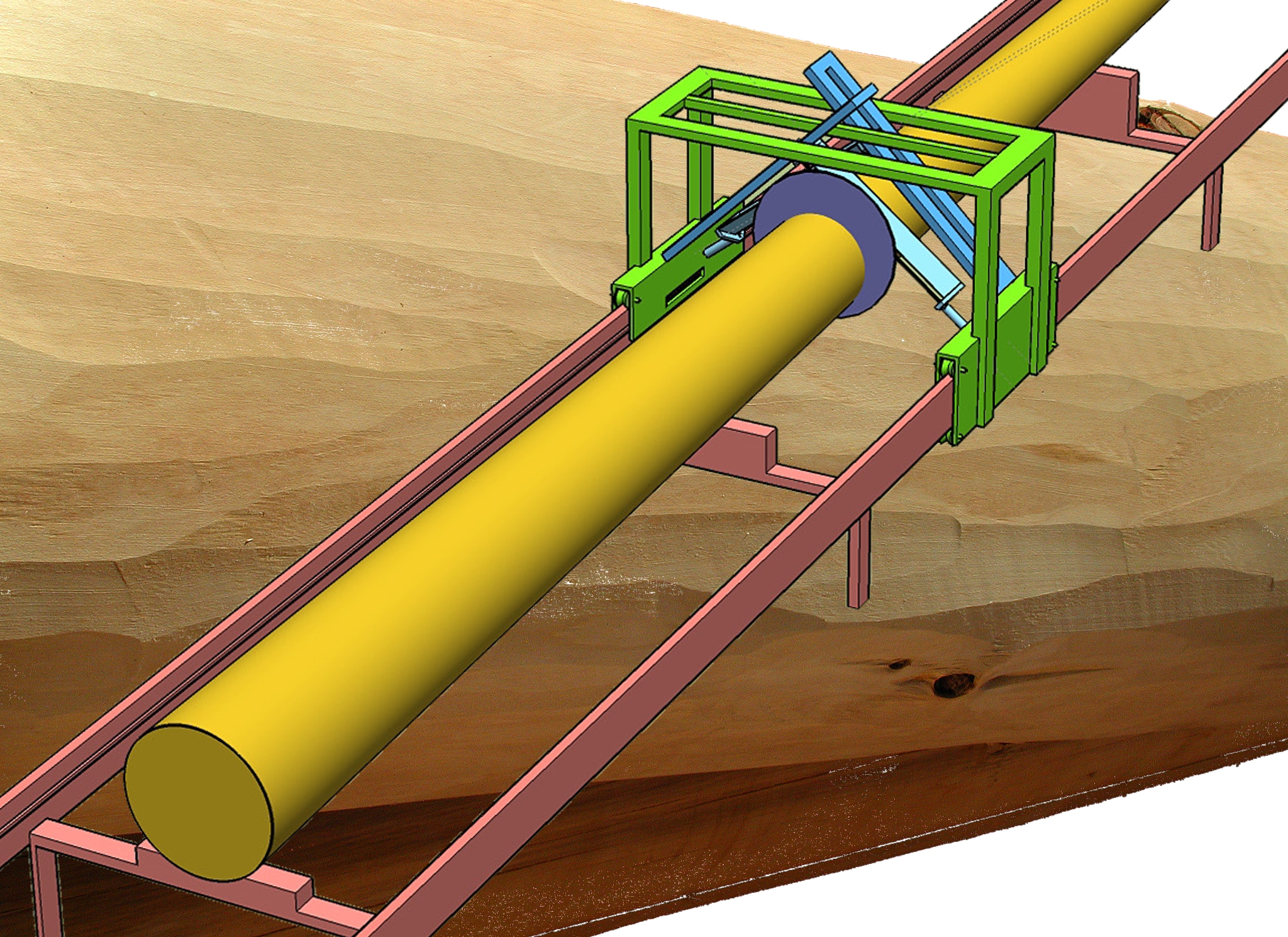

Log Lathe LL-41The log lathe LL-41 is "4 in 1" machine able to perform 4 following operations on logs:

Machine is shipped as a machine kit, owner is expected to assembling and setup the machine accordingly to provided assembling manual. |

1 unit in stock left New units |

|

RLM-machines: |

RLM stands for Rotary Log Mill or Rotary Log Moulder. These machines have 1 rotary type milling cutter head for log rounding and 2 to 5 (depending on a model) milling spindles, which can be used for profiling and some for multi-rip sawing of logs. Click here for more information about these machines... |

|

| LR-40, LR-60, LR-80, LR-100, LR-160, LR-160S LR-200, LR-320  |

Log rounding machinesThe machines are intended to mill stems into perfectly round dowels, poles and posts. If required pole pointing machine can be supplied. Click here for more information about these machines...

|

|

|

LTPS-150E, LTPS-150ME |

Log throuhg-pass "multiple-blade" rip-sawing machineThese multiple blade log rip-sawing machines intended for milling of dimensional or custom lumber from softwood and hardwood barked or debarked, dry or "green" stems. |

|

|

NM-10

|

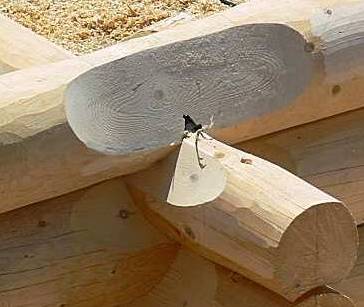

Notcher to mill Saddle Notch on round logs The machine is intended to mill sadlle notch on round logs produced on Woodlandia RLM-machiens or a log lathe LL-41 |

NEW PRODUCT! Available in |

|

NM-2, NM-2H, |

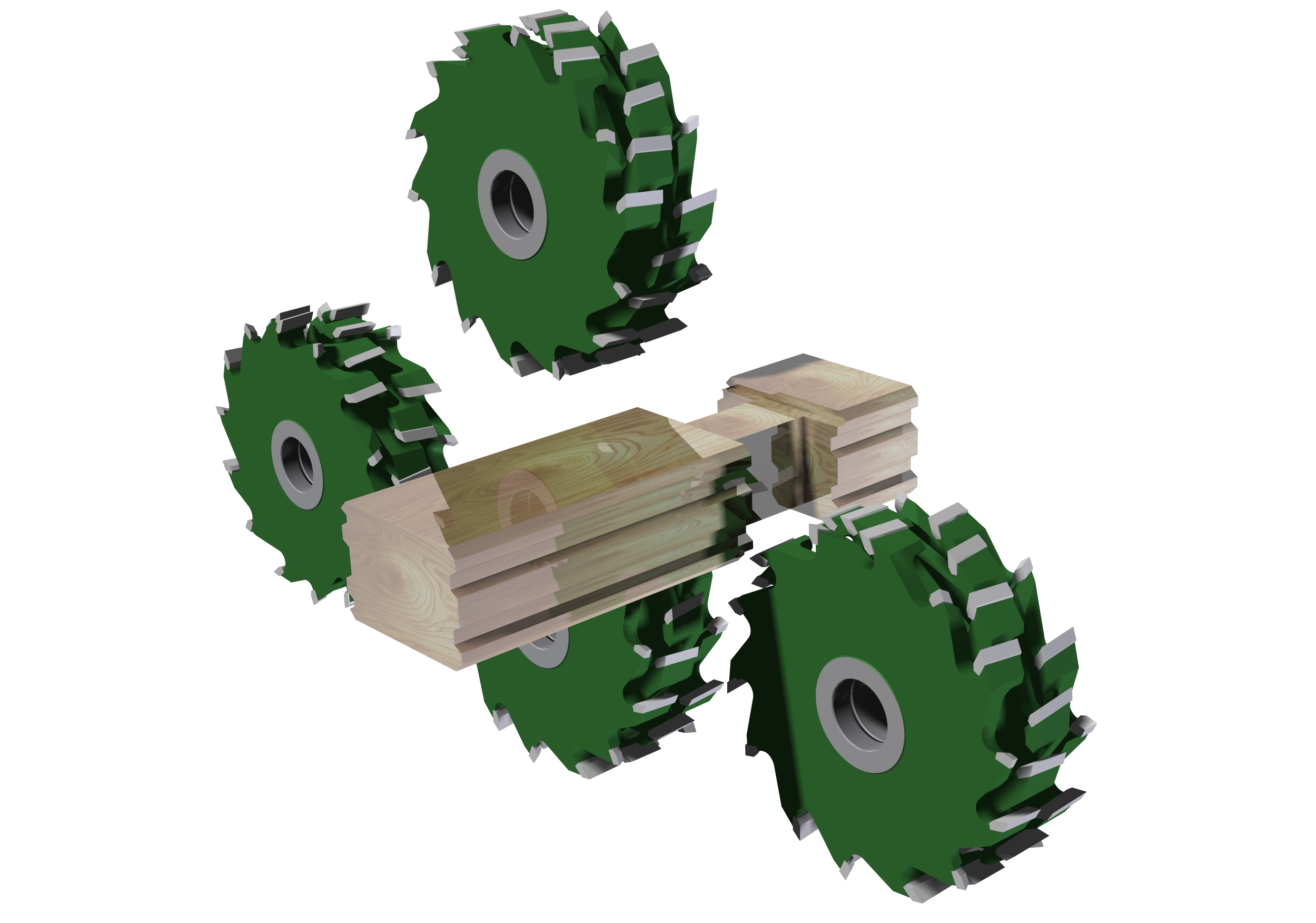

Notchers to Mill 90° Round Notch in round logs These machines mill regular Round Notch also known as saddle cope. A Round notch is made by simply cutting the exact contour of the log below into the bottom of the log going above it. The nother can be equiped with log drilling devices. Click here for further info |

|

|

NM-1, NM-3 |

Notchers to mill Round Notch in round logs in different angles (-30° .. +30°) These machines mill Round Notch (also known as saddle cope) in log in dofferent angles to allow log structure with corner conenctions other than 90°. Click here for further info |

|

|

MFN-1 |

Multi functional timber notching stationThis machines has modular configuration and it can perform 3 operations on a timbers with rectangular profiles:

Made by special orders only. Please inquire. |

By special orders Please inquire! |

|

LT-1, LT-2, LT-2H |

Log cross-cut (log trimming) machines are designed to cut logs to the proper size. |

|

|

LJ-1M, LJ-1M400 |

This machines are intended to mill slots in log ends. Such slots are used for window & door openings, log butt-to-butt interconnections. |

|

|

RoundMaster |

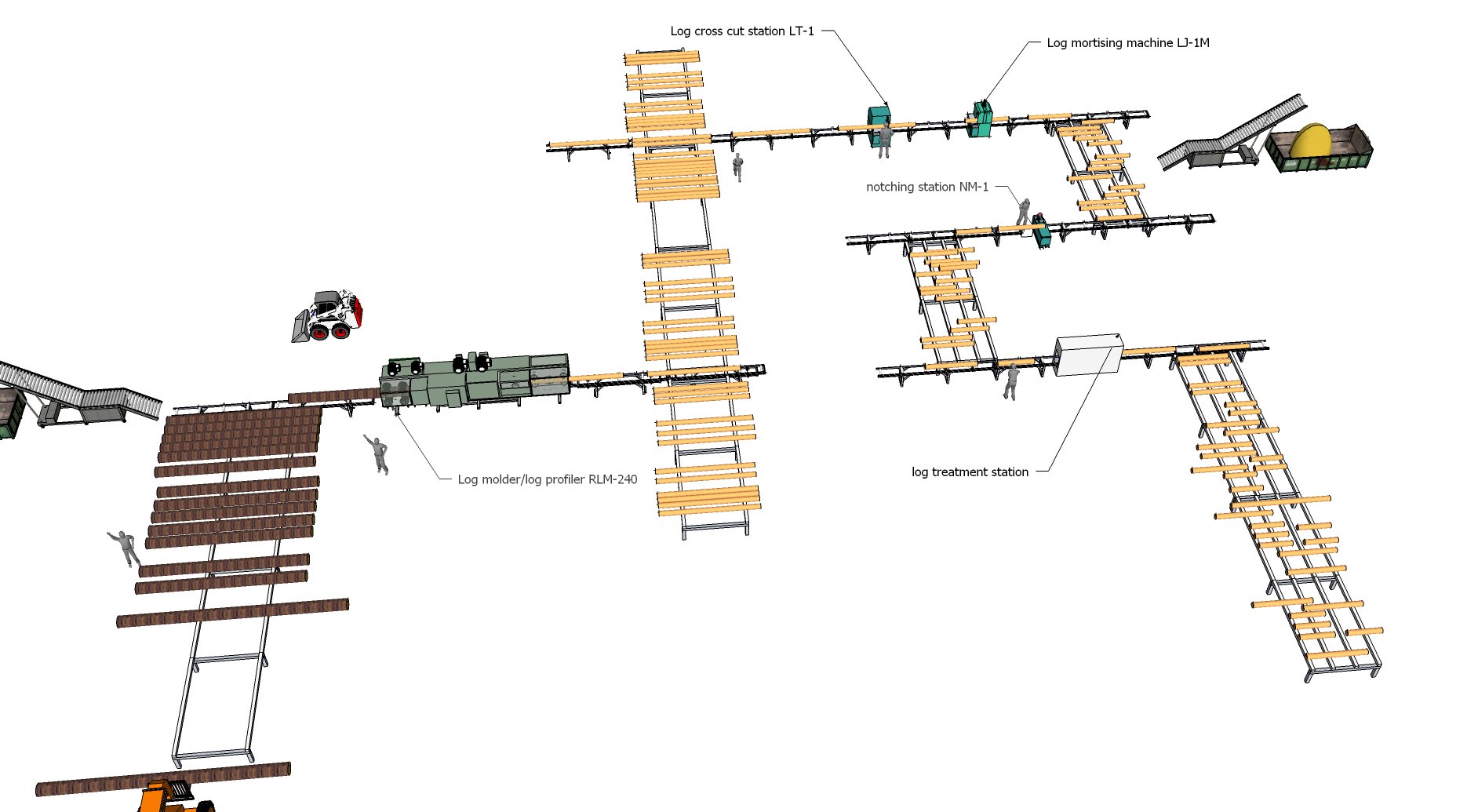

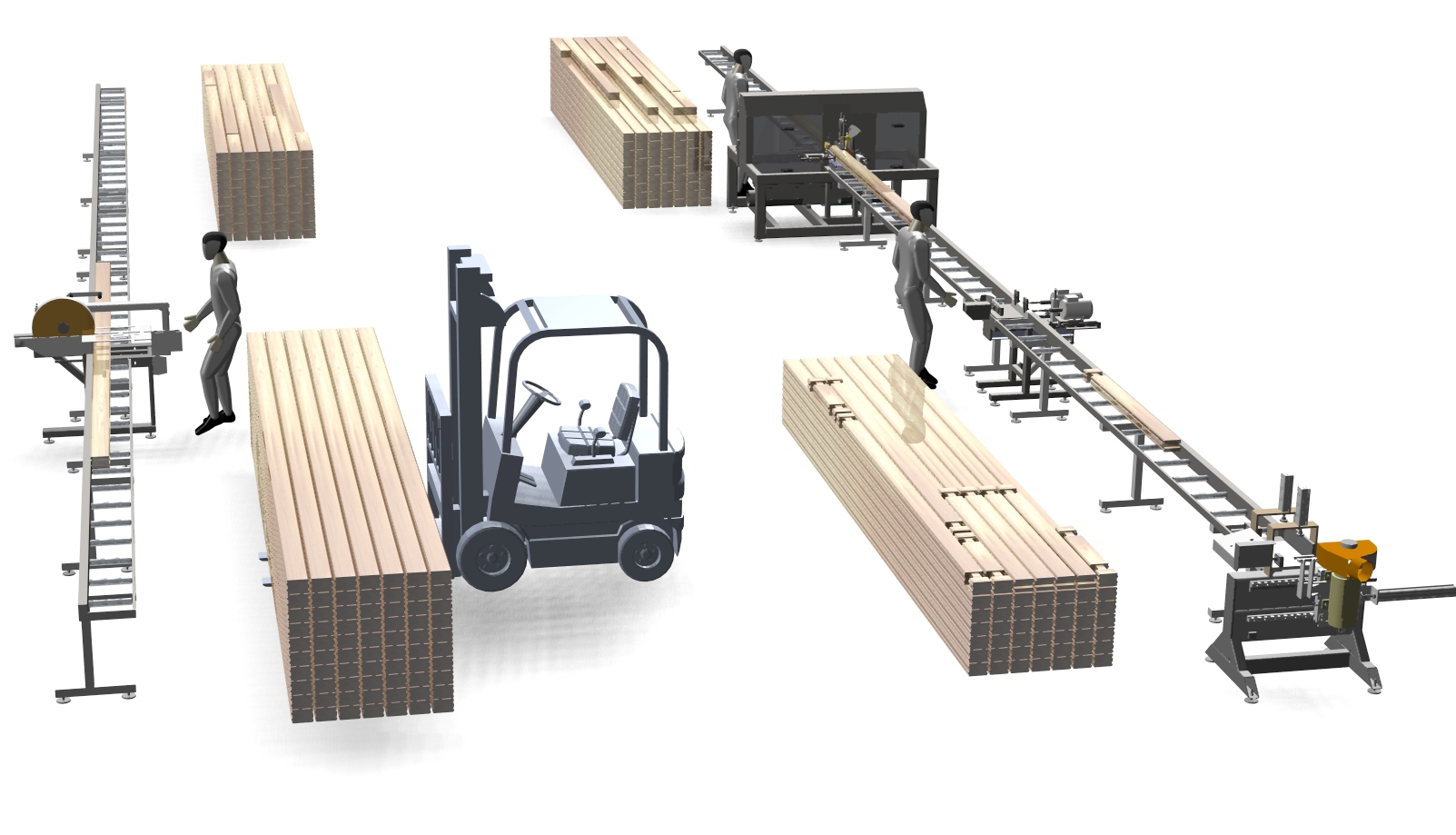

Log Home Manufacturing Lines

|

|

|

TimberMaster

|

Robotic CNC Log Home & Timber Frame milling system The computerised automated manufacturing line for production of log home shells & timber frame kits and its elements. |

NEW PRODUCT! Available in |

|

ARUNDA |

ARUNDA Dovetail milling systems Arunda systems allow to mill dovetail style joints in timbers to produce "iron free" joints for roof systems (rafters & trusses), timber frame and post & beam constructions. This Switzerland-made product has number of features among others there are:

Click here for more information about these systems... |

|

|

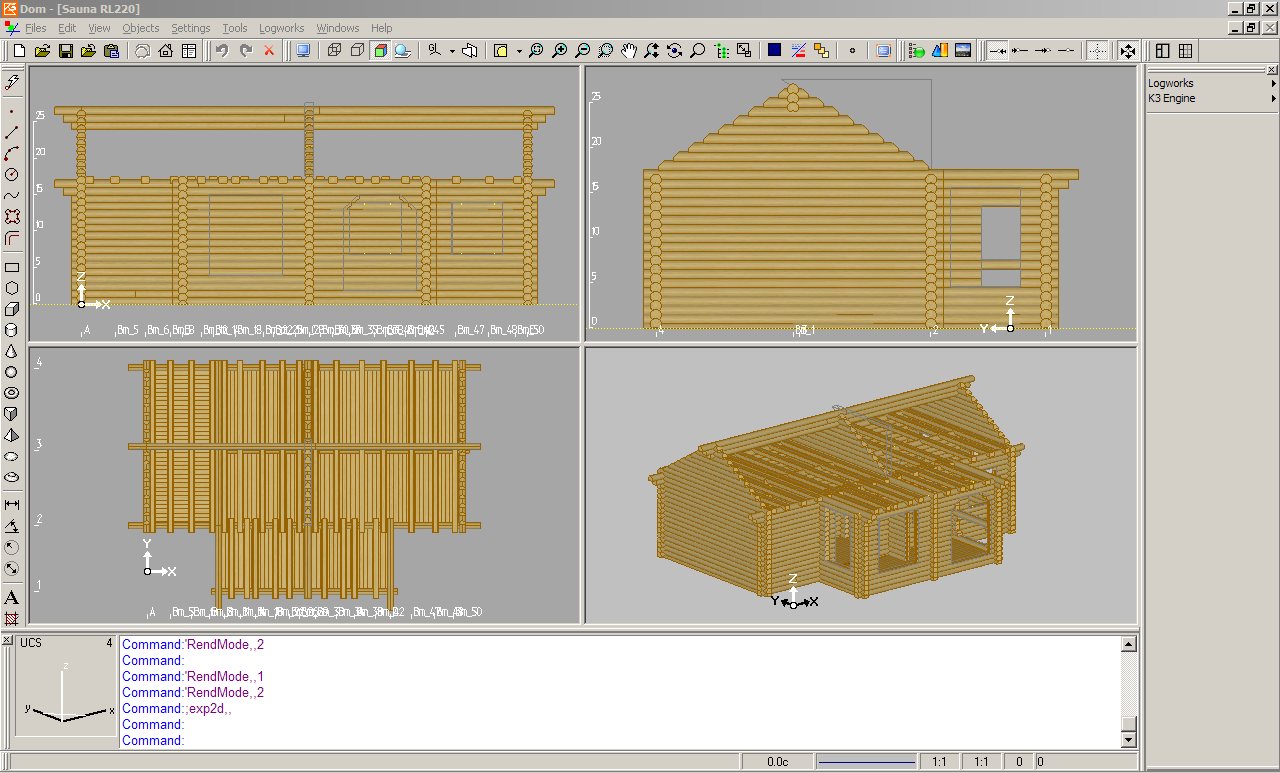

LogWorksDesigner

|

LogWorksDesigner Computer software The software for 3D modeliing of log homes and atomatical generation for the shop drawings and assembling documentation LogWorksDesigner 3D log home application for MS Windows helps designers and engineers to create visual images of log or timber structures as well as automatically produce shop drawings for manufacturing and documentation as well as for assembling of log homes. We run dedicated web site for this product, please visit: www.LogWorksDesigner.com to see examples of documentations, screencasts and screenshots. |

| Machines for Log Home Builders | Machines for Saw-Mills | |||

| Machine code | Brief description | Machine code | Brief description | |

|

CLP-1 |

CLP-1 emulates drawknife peeling process of hand crafted log home industry 1. Automated Debarking & Peeling |

RLM-machines: |

RLM stands for Rotary Log Mill or Rotary Log Moulder. These machines have 1 rotary type milling cutter head for log rounding and 2 to 5 (depending on a model) milling spindles, which can be used for profiling and some for multi-rip sawing of logs. Click here for more information about these machines... |

|

|

LL-41 |

Log Lathe LL-41The log lathe LL-41 is "4 in 1" machine able to perform 4 following operations on logs:

Machine is shipped as a machine kit, owner is expected to assembling and setup the machine accordingly to provided assembling manual. |

LTPS-150E, LTPS-150ME |

Log throuhg-pass "multiple-blade" rip-sawing machineThese multiple blade log rip-sawing machines intended for milling of dimensional or custom lumber from softwood and hardwood barked or debarked, dry or "green" stems. |

|

|

NM-10

|

Notcher to mill Saddle Notch on round logs The machine is intended to mill sadlle notch on round logs produced on Woodlandia RLM-machiens or a log lathe LL-41 |

LR-40, LR-60, LR-80, LR-100, LR-160, LR-160S LR-200, LR-320  |

Log rounding machinesThe machines are intended to mill stems into perfectly round dowels, poles and posts. If required pole pointing machine can be supplied. Click here for more information about these machines... |

|

|

NM-2, NM-2H, |

Notchers to Mill 90° Round Notch in round logs These machines mill regular Round Notch also known as saddle cope. A Round notch is made by simply cutting the exact contour of the log below into the bottom of the log going above it. The nother can be equiped with log drilling devices. Click here for further info |

|||

|

MFN-1 |

Multi functional timber notching stationThis machines has modular configuration and it can perform 3 operations on a timbers with rectangular profiles:

Made by special orders only. Please inquire. |

|||

|

LT-1, LT-2, LT-2H |

Log cross-cut (log trimming) machines are designed to cut logs to the proper size. |

|||

|

LJ-1M, LJ-1M400 |

Log cross-cut (log trimming) machines are designed to cut logs to the proper size. |

|||

|

RoundMaster |

Log Home Manufacturing Lines

|

|||

|

TimberMaster

|

Robotic CNC Log Home & Timber Frame milling system The computerised automated manufacturing line for production of log home shells & timber frame kits and its elements. |

|||

|

ARUNDA |

ARUNDA Dovetail milling systems Arunda systems allow to mill dovetail style joints in timbers to produce "iron free" joints for roof systems (rafters & trusses), timber frame and post & beam constructions. This Switzerland-made product has number of features among others there are:

Click here for more information about these systems... |

|||

|

LogWorksDesigner

|

ARUNDA Dovetail milling systems Arunda systems allow to mill dovetail style joints in timbers to produce "iron free" joints for roof systems (rafters & trusses), timber frame and post & beam constructions. This Switzerland-made product has number of features among others there are:

Click here for more information about these systems... |

|||